-

M.BoroomandiIn our co-operation over past ten years' time, we achieved win-win. Thank you for your quality products and attentive service. Our business has great

M.BoroomandiIn our co-operation over past ten years' time, we achieved win-win. Thank you for your quality products and attentive service. Our business has great

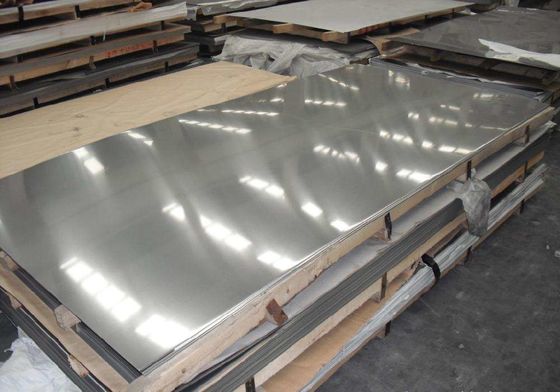

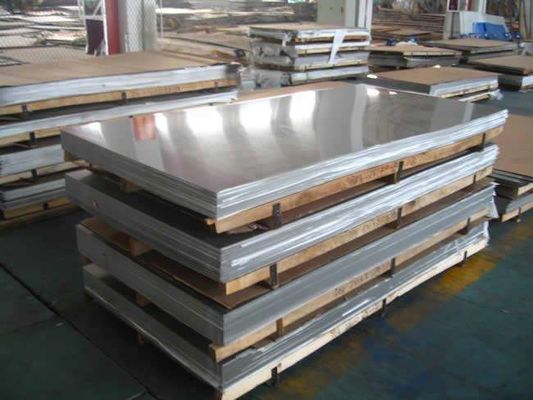

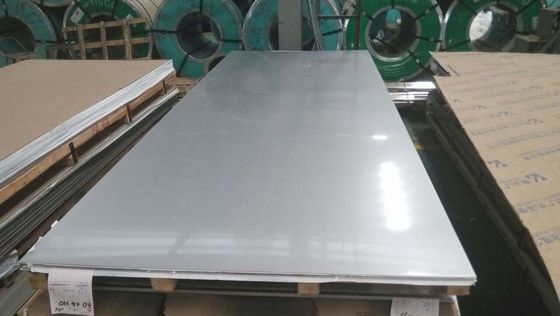

304h Hot Rolled Stainless Steel Flat Plate High Precision High Ductile Strength Excellent Malleability

| Place of Origin | Wuxi,China |

|---|---|

| Brand Name | Trump |

| Certification | ISO SGS |

| Model Number | 310S |

| Minimum Order Quantity | Negotiation |

| Price | Negotiation |

| Packaging Details | Waterproof Wooden Pallet,Standard Export Package |

| Delivery Time | 10-15working days |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 5000Tons per month |

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Application | Electrical Equipment | Standard | JIS, AISI, ASTM, GB, DIN, EN |

|---|---|---|---|

| Material | 201/304/304L/316/316L/430 | Length | 1000-6000mm |

| Width | 1000-3000mm | Thickness | 0.1-10mm |

| Technique | Cold Rolled | Hardness | ANN |

| High Light | stainless steel sheet metal,mild steel sheet |

||

| Surface Finish | Characteristics | Application |

| 2B | Finshed by heat treatment, pickling after cold-rolling,followed by skin pass line to me more brighter and smooth surface | General application, medical equipment, construction material, Kitchen utensile |

| BA | Bright treatment after cold rolling | Kitchen utensile, kitchen ware, Electronic equipment, building construction |

| No.1 | Finshed by hot-rolling, annealing and pickling, characterized by white pickled surface | Chemical industry, equipment, industrial pipe and tanks |

| No.4 | Polishing with No.150 to No.180 mesh abrasives | Food processing activities, hospital equipment |

| HL | Finished by continous liner polishing | Building construction,vehicles,kitchen |

| 8K | A mirror-like reflective surface by polishing with finer abrasives over 800 mesh | Reflector, mirror, interior-exterior decoration for building |

Product Description

- Standard: ASTM A240,ASTM A480,ASTM A167,ASTM A176

- Material: 201,202,301,304,304L,304N,XM21,304LN,305,309S,310S,316,316Ti,316L,316N,316LN,317,317L,321,347,329,405,409,430,434,444,403,410,420,440A,etc.

- Specifications:

- Thickness: 0.01-200mm

- Width: 1m,1.22m,1.5m and 1.8m.

- Length: 2m,2.44m,5.8m,6m.

- Surface: No.1, 2B, BA, NO.4, 8K mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc.

-

What is 310S stainless steel?

310S stainless steel is austenitic chromium-nickel stainless steel, which has good oxidation resistance, corrosion resistance, and high temperature resistance. Because of the higher percentage of chromium and nickel, it has much better creep strength and can continue to work at high temperatures. Has good high temperature resistance. Due to the high content of nickel (Ni) and chromium (Cr), it has good oxidation resistance, corrosion resistance, acid and alkali resistance, and high temperature resistance. High temperature resistant steel pipes are specially used for the manufacture of electric furnace tubes and other occasions. After the content, due to its solid solution strengthening effect to improve the strength, the chemical composition of austenitic stainless steel is based on the addition of molybdenum, tungsten, niobium and titanium based on chromium and nickel. Therefore, it has high strength and creep strength at high temperature. Melting point is 1470 ° C, 800 ° C begins to soften, and allowable stress continues to decrease.

-

310S Chemical Composition

Material C Si Mn P S Ni Cr 310S ≤0.08 ≤1.00 ≤2.00 ≤0.045 ≤0.03 19.0~22.0 24.0~26.0 310S Mechanical Properties

Material Yield Strength

N/mm2

Tensile Strength

N/mm2Elongation

(%)310S ≥205 ≥520 ≥40 Surface

1D—The surface has discontinuous particles, which is also called matte. Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling.

2D—Slightly shiny silver-white. Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling.

2B—Silver white and better gloss and flatness than 2D surface. Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling + quenching and tempering rolling.

BA—The surface gloss is excellent and has a high reflectivity, just like the mirror surface. Processing technology: hot rolling + annealing shot peening pickling + cold rolling + annealing pickling + surface polishing + quenched and tempered rolling.

No.3—has better gloss and rough surface. Processing technology: Polishing and tempering rolling of 2D products or 2B with 100 ~ 120 abrasive materials.

No.4—has better gloss and fine lines on the surface. Processing technology: Polishing and tempering rolling of 2D products or 2B with 150 ~ 180 abrasive materials.

HL—Silver gray with hair streaks. Processing technology: Polish the 2D product or 2B product with a suitable size of abrasive material to make the surface appear continuous grain.

MIRROR—is in a mirror state. Processing technology: 2D or 2B products are ground and polished to a mirror effect with a suitable abrasive material. -

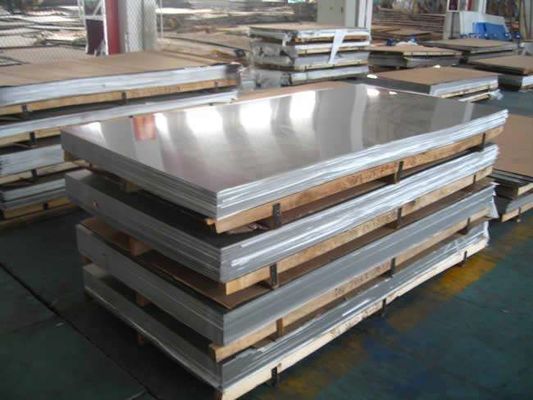

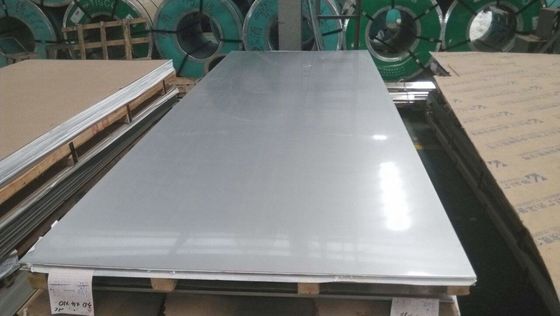

Products' Photos

-

-

Applications:

construction field, ships building, petroleum and chemical, war and electricity, food processing and medical industry, boiler heat exchanger, machinery and hardware field

Competitive Advantage:

- Packaging

- Price

- Prompt Delivery

- Quality Approvals

- Service

- Small Orders Accepted

- Experienced staff